X40 PRO High Temperature upgrade (for Weedo X40V1 and Weedo X40V2)

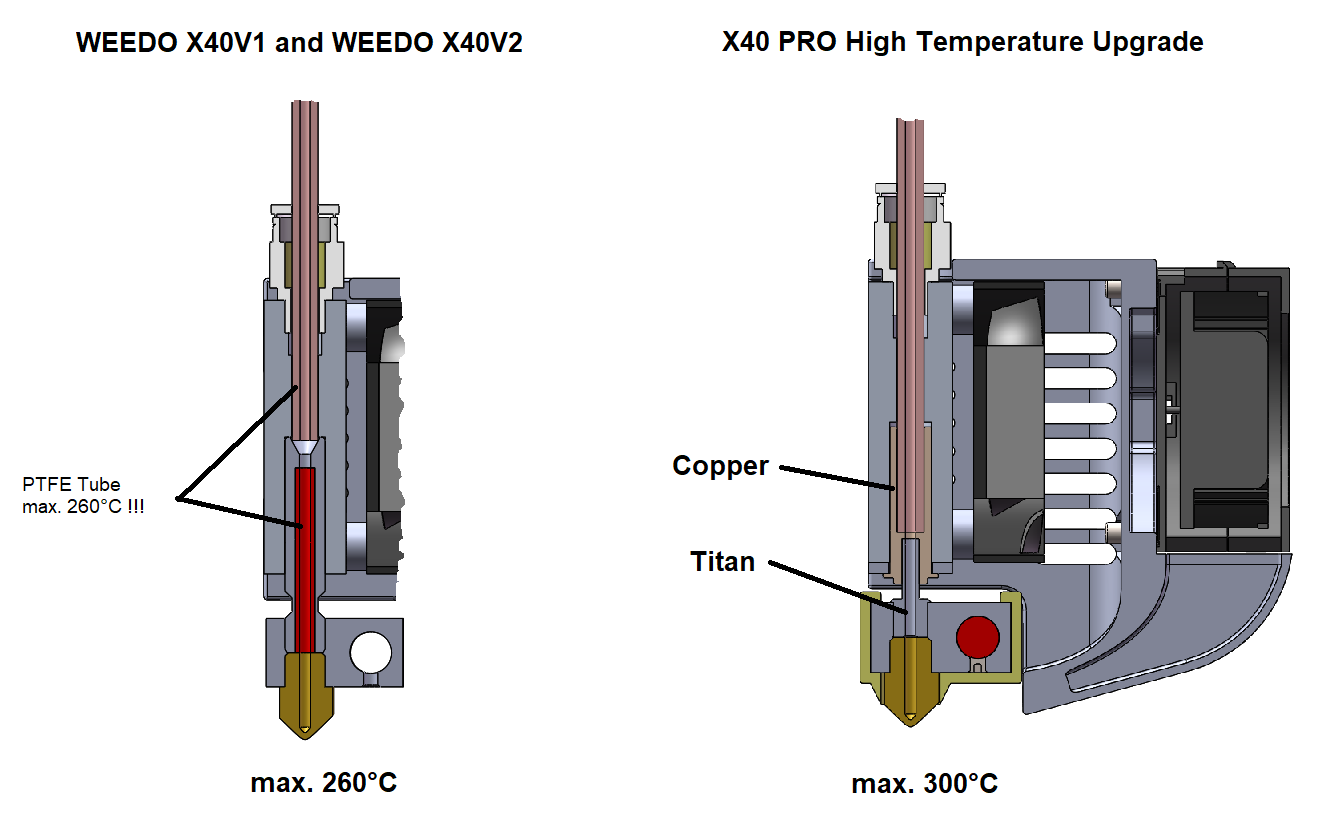

The Weedo X40V1, V2 and V3 are equipped with 24V 50 Watt cartridge heaters. These heating cartridges not only allow rapid heating, but also temperatures of over 300°C. The Weedo V1 and V2 are sealed at 260°C because a stainless steel heat brake with PFTE hose is used. PFTE decomposes at temperatures above 260°C with highly toxic fumes. The fumes are said to be so toxic that even animals can die in poorly ventilated rooms. However, Weedo has shown with the Weedo X40V3 and ME40 that with the right heat brake it is possible to operate the printer at temperatures of up to 300°C.

In this article I would like to show you how you can easily convert the X40 PRO version to the X40 PRO HT (High Temperature) versions.

See Youtube Video Weedo X40 PRO High Temerature upgrade.

Danger:

| Attention, a small guarantee is given for the conversion. Conversion at your own risk! The construction has been extensively tested. But if you don't replicate it exactly and use other parts, materials, then in the worst case it can lead to a fire! The construction was also not checked for any toxic gases that might be produced. However, the hardware also showed no abnormalities that the PTFE hose is too hot. Never use the stainless steel Heatbrakes from the Weedo X40V1 and X40V2 for the high temperatures. Otherwise, highly toxic gases can be produced as a result of the decomposition of the PFTE! |

The Heatbrake

The Weedo X40 Heatbrake is a 31mm long tube that has an M6 thread at the heater end and a 6mm diameter at the other end. The heat brake has the task of separating the hot part from the cold part. If possible, only the heating block and the nozzle should be hot and the temperature should not fluctuate greatly.

The Weedo X40V1 and V2 use a stainless steel tube with an inside PTFE tube and a powerful fan on the cooler (Infos). This construction works well up to about 250°C if the pullback is not set too high. Problems can arise if the retraction is too great or if the temperatures are higher, since the heat travels too far up and the filament softens too early. The result is constipation. At temperatures above 260°C, the PFTE would decompose and the printer would be damaged.

In order to be able to print temperatures above 260°C, a bimetal heat brake made of titanium and copper is therefore required. Titanium conducts heat poorly and copper very well. This combination keeps the hot part hot and the cold part well below 260°C.

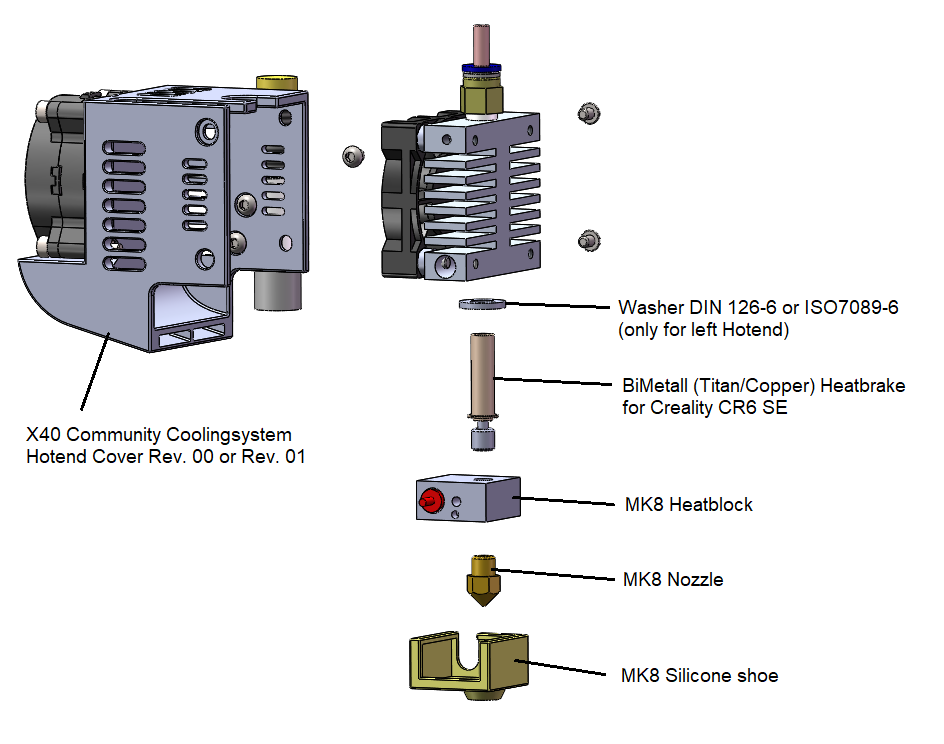

Luckily, it turned out that the BiMetal Heatbrake for the Creality CR-6 SE is only one millimeter shorter than that of the Weedo X40. With one washer you get almost exactly the right size to continue using the X40 PRO cooling system.

- Noname BiMetall Heatbrake for Creality CR-6 SE (Tested Version)

- Brozzle BiMetall Heatbrake for Creality CR-6 SE

- Tuning Part MK8 Heatblock from Micro Swiss (Recommendation)

- Steel or Ruby Nozzle MK8

Advantages of a BiMetal Heatbrake

Thanks to a bimetal heat brake, the heat does not migrate upwards even with many retractions. This ensures that the filament does not melt too early and does not clog the nozzle. A bimetal heabrake also improves the behavior of low-temperature materials such as PLA. In addition, a larger temperature gradient between the hot and cold part is possible. This allows high-temperature filaments to be processed.

Of course, you can also use the BiMetal Hearbrake without a firmware update. However, the maximum temperature of 260°C then remains. However, you have to carry out a PID tuning, since the bimetal heat brake has a different behavior to which the control loop must be adapted.

Disadvantages of a BiMetal Heatbrake

Some filament can become blocked if the cooling is set too high. The blockage can be easily unblocked by increasing the temperature and reducing or stop the cooling.

For me, the blockage has only occurred with the Colorfabb PA Neat filament.

The problem can also occur if the retraction is too large.

X40 PRO Firmware for High Temperature

The firmware must also be adapted for the higher temperatures. The firmware that is enabled for higher temperatures was appended with the abbreviation HT. You will soon be able to download the new firmware in the HT version from the X40 PRO firmware page.

You can also use the upgrade with all other firmware variants. However, the printing temperature is then limited to a maximum of 260°C.

Ultimaker Cura for High Temperature

Cura configuration for the Weedo X40 PRO is also limited to 260C° in the current version. With the next release, the Cura configuration will be activated up to 300°C.

Setup

With the BiMetal Heatbrake it is not easy to get a constant temperature. With the right PID parameters you can get it between 200°C and 260°C, but above 260°C the temperatures start to fluctuate for me. I haven't found a better solution until now.

My current PID parameters:

- P11.83

- I0.94

- D37.22

In order to avoid the Heating Failed Error, both heating cartridges should be identical and the same parameters should also be used. Since the firmware only supports one PID set for both nozzles, this should always be the case.

Filament for High Temperature printing

Especially with technical filaments such as PC and PA, the difference in the Cura printing profiles between visual and engineering becomes clear.

With the Visual Profile, good optics have priority, so cooling is used here. The strength, especially the layer adhesion suffers here. The engineering profiles are optimized for strength and precision, which is why cooling is significantly reduced or even switched off for some filaments. With PC and PA, the layer adhesion is therefore very good, but you have to accept optical defects if necessary.

The following filaments are tested and Cura print profiles are created:

- Colorfabb PA Neat

- 3DJake PCTG

- Polymaker PolyMax PC

- Fiberlogy PCTG

- AddNorth Adura Nylon

- Fillamentum CPE HG100