Automatic shrinkage compensation with Cura 5.X

In the case of plastic parts that are produced by melting the plastic and producing the desired shape (e.g. injection moulding, deep drawing and also FDM printing), the properties of the plastic play a central role. During the cooling process of the plastic part, the part becomes smaller, it shrinks. Shrinkage is the main reason for warping in FDM printing. In order for the finished part to have the desired dimensions, shrinkage, depending on the material selected, must be taken into account during production. For a long time, this was very time-consuming with Cura, as the model had to be scaled up accordingly.

From Cura 5.0.0 there is now the possibility to specify the shrinkage compensation in the material file and Cura takes the shrinkage into account automatically. Since the shrinkage is usually different in the XY printing direction than in the Z direction, this can even be specified separately. With Cura 4.X you can compensate for the shrinkage by scaling the model accordingly.

|

Every little change in the plastic affects the shrinkage. You cannot therefore simply transfer the shrinkage from one ABS to the other. The shrinkage must be determined for each filament. The influence of the material color is very small and can be neglected in FDM printing.

|

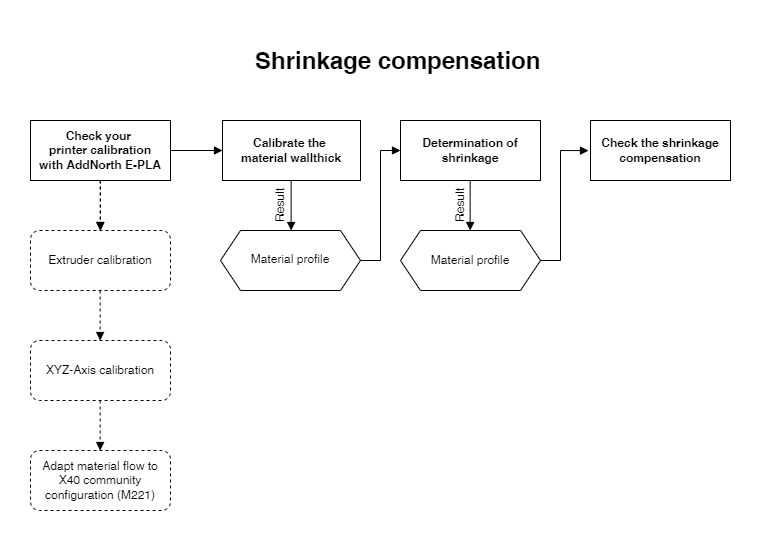

Process

Specify shrinkage compensation in the Cura 5.X material file:

Only values deviating from the default value 100% are given. Specifying 100% shrinkage compensation does not change the dimensions, but makes the system a little slower!

<cura:setting key="material_shrinkage_percentage_xy">100.58</cura:setting>

<cura:setting key="material_shrinkage_percentage_z">100.30</cura:setting>

Determination of the shrinkage

Appropriate measuring equipment is required for a professional and precise determination of the shrinkage. Therefore, we simplify the process considerably and settle for an approximation.

When determining shrinkage, it is important to use a printer that is calibrated as precisely as possible. Imagine the printer receives the command via the gcode to move 10mm in the X direction, but actually only moves 9.8mm. Even without shrinking, the printed component would be too small because the printer was not calibrated. The result would be excessive shrinkage.

|

Calibrate your FDM printer. We used AddNorth E-PLA for calibration and reference material. The material appears to show very little shrinkage, since the components were dimensionally stable even without compensation. You can read about how to calibrate an FDM printer on the Teaching Tech homepage. |

Step 1: Check you printer calibration (unique)

To verify the correct calibration, please print a 20mm cube from AddNorth E-PLA with the Weedo X40 PRO printing profile Engineering Normal (layer height 0.2mm). At this print, the flow rate must be 100%. Measure the cube. With a proper calibration, the cube should be 20mm +/-0.05mm. If the deviation is larger, the calibration is incorrect and must be corrected accordingly.

The AddNorth E-PLA has almost no shrinkage, making it perfect for calibration.

Step 2: Check and adjust you wallthickness (with every material)

Calculation of material flow rate:

New flow rate = Nominal wallthickness / Measured wallthickness * Previous flow rate

Example:

Nominal wallthickness = 0,4mm

Average measured wallthickness = 0,455mm

Previous flow rate = 100%

=> 87,9% Flow rate

Step 3: Determine and check the shrinkage (with every material)

- Download 40mm x 20mm x 20mm Calibration cuboid

- Material flow and shrinkage compensation calculation tool (Open Office spreadsheet)

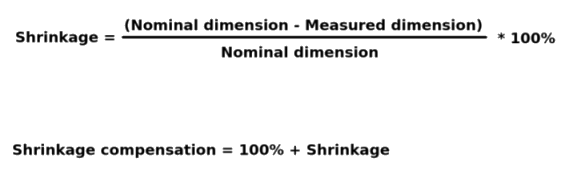

Calculation of shrinkage compensation:

Example:

Nominal dimension = 40mm

Measured dimension = 39,8mm

=> 100,5% Shrinkage compensation

Some manufacturers, such as e.g. Extruders indicate the shrinkage in the data sheet. However, this value does not appear to agree with the shrinkage in FDM printing.

We should use the determined values for everyone. It would therefore be nice if you and your results let us know so that we can include them in the table.

E-mail to database(at)x40-community.org

Shrinkage compensation for Cura 5.X:

The shrinkage of the component is changed by the adhesion to the print bed, so the actual shrinkage of the material, e.g. an injection molding process, cannot be transferred to the FDM print. The print bed and the adhesion to the print bed therefore has a great influence on the shrinkage compensation.

A print bed with BuildTak PEI film was used to determine the values.

State: 2022-06-16

| Manufacturer | Material | XY-Shrinkage | Z-Shrinkage |

| AddNorth | E-PLA, yellow | 100.00% | 100.00% |

| AddNorth | Adura (Nylon), olive | 100.90% | 100.90% |

| AddNorth | PETG, mid blue | 100.00% | 100.00% |

| AddNorth | Texture Flare, grey | 100.00% | 100.00% |

| AddNorth | PLA Wood | 100.00% | 100.00% |

| 3DJake | niceABS, black | 101.00% | 101.00% |

| ColorFabb | PHA/PLA, black | 100.00% | 100.00% |

| ColorFabb | PHA, black | 100.00% | 100.00% |

| ColorFabb | NGEN, red | 100.00% | 100.00% |

| 3DJake | PLA, black | 100.00% | 100.00% |

| 3DJake | PETG, blue | 100.00% | 100.00% |

| Eryone | PETG, grey | 100.00% | 100.00% |

| Extrudr | BioFusion, gold | 100.50% | 100.00% |

| Extrudr | DuraPro ASA, black | 101.00% | 100.00% |

| Extrudr | FlexMedium | ||

| Extrudr | GreenTec, silver | 100.00% | 100.00% |

| Extrudr | GreenTec Pro, black | 100.00% | 100.00% |

| Extrudr | PETG, glow in the dark | 100.50% | 100.00% |

| Fiberlogy | ASA, light green | 100.50% | 100.50% |

| Fiberlogy | EasyPETG | 100.50% | 100.50% |

| Fiberlogy | EasyPLA | ||

| Fiberlogy | FiberSatin | 100.60% | 100.60% |

| Fiberlogy | FiberSilk | 100.60% | 100.60% |

| Fiberlogy | Fiber Wood | ||

| Fiberlogy | HIPS, white | 100.50% | 100.50% |

| Fiberlogy | Impact PLA, black | 100.00% | 100.00% |

| Fiberlogy | Mineral PLA | 100.00% | 100.00% |

| Fiberlogy | PCTG, white | 100.00% | 100.00% |

| Fiberlogy | PP, white | ||

| Fillamentum | CPE-HG100,black | 100.00% | 100.00% |

| Fillamentum | NonOilen | 100.46% | 100.46% |

| FormFutura | ABSpro Flame Retardant, black | 100.50% | 100.00% |

| FormFutura | ApolloX ASA | 100.50% | 100.50% |

| Inkrayon | Perfamance ABS, black | 100,75% | 100.00% |

| Inkrayon | Perfamance PLA, green | 100.00% | 100.00% |

| Janbex | PLA, black | 100.00% | 101.26% ??? |

| Material4Print | PLA | 100.00% | 100.00% |

| Material4Print | PETG, black | 100.00% | 100.00% |

| Material4Print | ASA | ? | ? |

| Material4Print | PMMA | ? | ? |

| Polymaker | PolyTerra PLA | 100.00% | 100.00% |

| Polymaker | PolyMax PLA | 100.00% | 100.00% |

| Polymaker | PolyFlex TPU95 | ||

| Prusament | PVB | ||

| Verbatime | PLA | 100.00% | 100.00% |

| Verbatime | PETG | ||

| Verbatime | DuraBio | 100.00% | 100.00% |