Multi-material 3D printing

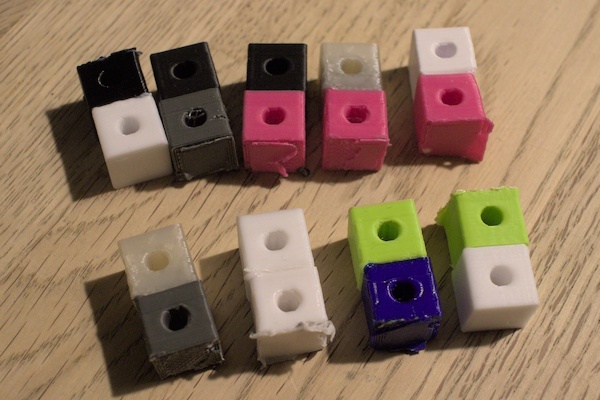

Multi-material 3D printing is a 3D printing that consists of two or more components that are connected permanently or movably during printing. The best known is the two color printing with an FDM Idex printer. However, it is not only possible to combine two different colors from the same material. In this article I want to show the possibilities and problems.

Please also note the shrinkage issue.

Environmental Protection

Material combinations

Suitable material combinations enable interesting technical solutions. Typical examples for the combination of two plastics A and B are:

| Material A | Material B |

| Base color | Contrast color |

| Opark | Transparent |

| Hard / Stiff | Soft / Elastic |

| Standard material | ESD material |

| Standard material | Wear-resistant material |

Combinations with each other are also possible.

Requirements for combining different materials

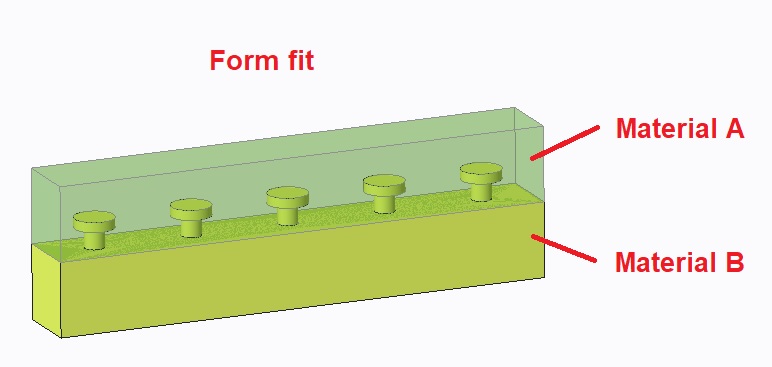

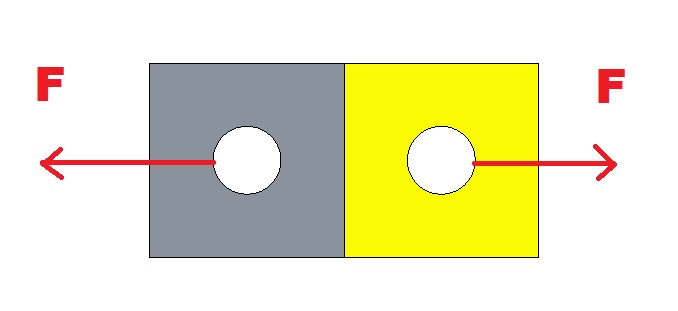

Two different materials can be combined into one component in different ways. Two types of plastic can be fused together on the surface if they are compatible with each other. The compatibility is the better the more similar the materials are in the polymer composition. Materials that have a very different melting point can therefore not be connected to each other. However, two materials can also be connected to one another via a form fit. In the case of incompatible materials that do not enter into a material connection, you can also create flexible connections in this way.

Material / Filament compatibility

- Standard PLA = Material4Print PLA

- Tough PLA = Fiberlogy Impact PLA

- PETG = 3DJAKE PETG

- PCTG = Fiberlogy PCTG

- FiberSilk = Fiberlogy FiberSilk

- ASA = Fiberlogy ASA

- GreenTec Pro = Extrudr GreenTec Pro

- NonOilen = Fillamentum NonOilen

- DuraBio = Verbatim DuraBio

- PVB = Prusament PVB

- HIPS = Fiberlogy HIPS

- TPU = Polymaker PolyFlex TPU95A

- PP = Fiberlogy PP

- OBC Polyethylene = Addnorth OBC Polyethylene

- I150-PF = Igus I150-PF

- PMMA = Material4Print PMMA

- PHA = ColorFabb ALLPHA

| Material A / Material B |

Standard PLA | Tough PLA | PETG | PCTG | FiberSilk | FiberSatin | ASA | GreenTEC Pro | NonOilen | DuraBio | PVB | HIPS | TPU | PP | OBC Polyethylene | PMMA | I150-PF | PHA |

| Standard PLA | 3 | X | 1 | 1 | 2 | X | 1 | X | 3 | 1 | ? | 0 | 2 | X | 0 | 1 | 1 | ? |

| Tough PLA | 3 | 3 | 1 | X | X | 2 | X | 3 | 3 | 1 | ? | X | 2 | 1 | 0 | 1 | 1 | ? |

| PETG | X | 1 | X | 1 | 2 | X | 3 | X | 0 | 3 | ? | X | X | 1 | 0 | 1 | X | ? |

| PCTG | 1 | 1 | 1 | 3 | 1 | 1 | 1 | 1 | 0 | 1 | ? | 1 | 2 | X | X | 0 | 3 | ? |

| FiberSilk | 2 | X | 2 | 1 | X | 2 | 1 | X | X | 1 | ? | X | X | 0 | 0 | 0 | 1 | ? |

| FiberSatin | X | 2 | 1 | X | 2 | X | X | 3 | 3 | 3 | ? | 1 | X | 1 | X | X | 1 | ? |

| ASA | 1 | X | 3 | 1 | 1 | 3 | 3 | 3 | 1 | 2 | ? | 1 | 0 | 1 | 0 | 3 | 3 | ? |

| GreenTEC Pro | 3 | 3 | 2 | X | 3 | X | X | X | 3 | 3 | ? | 1 | 2 | X | 0 | 3 | X | ? |

| NonOilen | 3 | 3 | 0 | 0 | X | 3 | 1 | 3 | X | 0 | ? | 1 | X | 0 | 0 | 0 | 0 | ? |

| DuraBio | X | X | 3 | 1 | 1 | X | 2 | 3 | 0 | 3 | ? | 0 | 1 | X | 0 | 2 | 3 | ? |

| PVB | X | ? | ? | ? | ? | ? | ? | ? | ? | ? | 3 | ? | ? | ? | ? | ? | ? | ? |

| HIPS | 0 | 3 | 1 | 1 | 1 | 1 | X | 1 | 1 | 0 | ? | 3 | 0 | 1 | 0 | X | 0 | ? |

| TPU | 2 | 2 | X | 2 | 3 | 3 | 0 | X | 1 | 1 | ? | X | X | 1 | 0 | 2 | X | ? |

| PP | 3 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | X | 0 | ? | 1 | 1 | 3 | 3 | 0 | 0 | ? |

| OBC Polyethylene | 0 | X | 0 | X | 0 | 0 | 0 | 0 | 0 | 0 | ? | 0 | 0 | 3 | 3 | X | 1 | ? |

| PMMA | X | 1 | 1 | 0 | 0 | 3 | 3 | 3 | X | 2 | ? | 3 | 2 | 0 | 0 | X | X | ? |

| I150-PF | 1 | 1 | 3 | X | 1 | 1 | 3 | 0 | 0 | 3 | ? | 0 | 1 | 0 | 1 | 2 | 2 | ? |

| PHA | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | X |