Adjust belt tension from the Weedo X40

Attention:

|

Weedo does not currently offer the toothed belt as a spare part. If the belt breaks, then you have a big problem. You can buy the belt by the meter, but finding the right length and attaching it to the print head or print bed is an almost unsolvable problem. So be careful with your toothed belt. When used properly, a toothed belt will last the life of the printer. The toothed belt tension is set incorrectly in many cases, which means that the toothed belt tears much more quickly and bearings are destroyed or damaged. In the case of a toothed belt, the force and accuracy are guaranteed by the positive locking of the teeth. A toothed belt therefore does not require high belt tension. Set the belt tension as low as possible. If the belt slips, you can always adjust it. A layer offset is not always attached to the belt. If the acceleration values are too high, the motor can also lose steps. A higher belt tension does not solve the problem, but creates additional ones. Also make sure that the belt does not get any oil and grease. Over time, oils and fats damage the material and the belt tears! |

Effect of belt tension on offset and axis calibration

It is important to know that the belt tension can affect the offset and also the axis calibration. If you change the belt tension in the X-direction, the offset will normally also change. It follows that the following order should be followed:

- Adjust belt tension

- Check the axis calibration with the left print head and repeat it if necessary

- Set the XYZ offset of the nozzles to one another

More Information see Set the XY offset

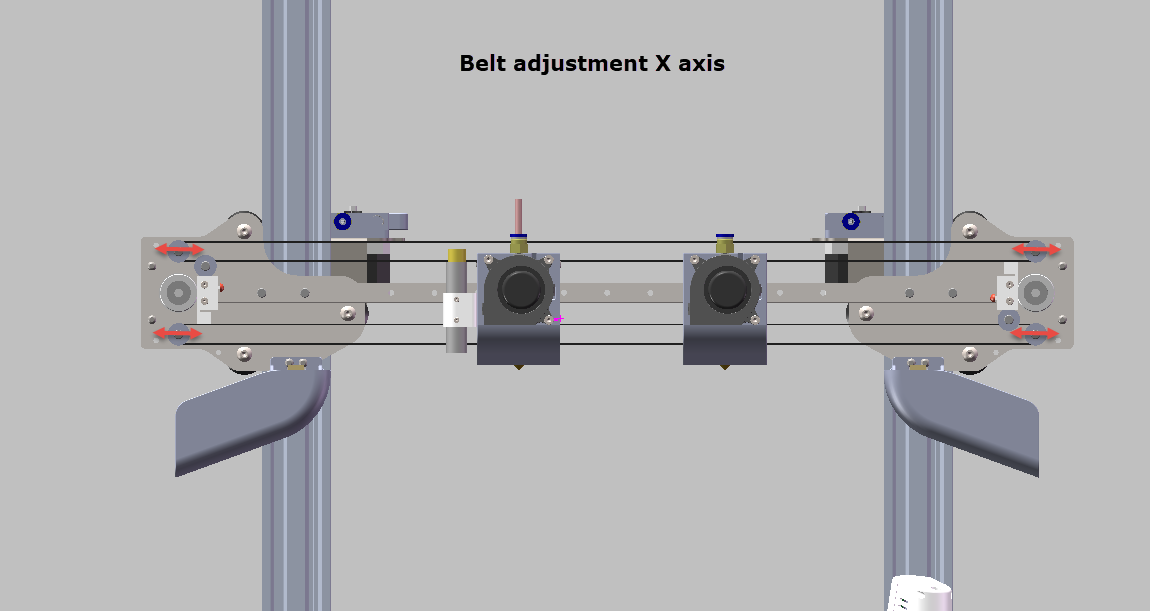

Belt adjustment X-axis

To adjust the belt tension from the X axis you need to remove the cover in front of the stepper motor. As shown in the picture, the deflection rollers can be moved into a slot for belt tensioning. The process is not very easy. Take your time. With the screws you can not only tighten the belt, but also adjust the offset of the extruders to each other.

The offset from the extruder can only be corrected by software in the range of +/-2.5mm! If the offset is larger, you have to correct it using the deflection rollers.

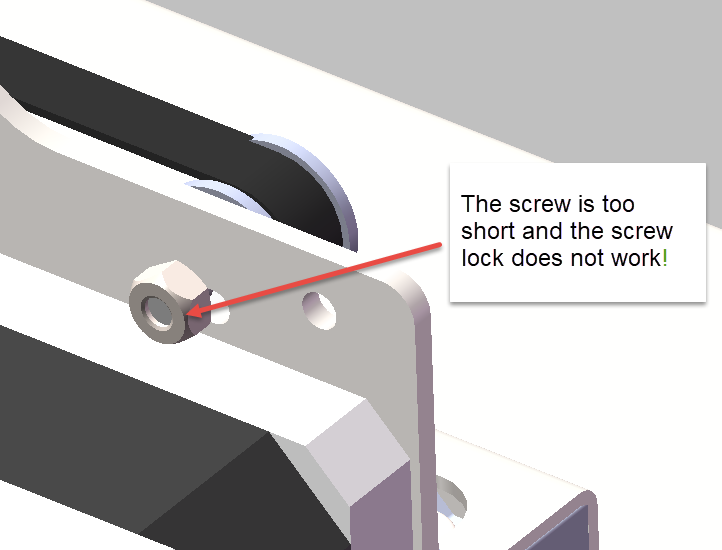

Attention:

The deflection rollers are provided with a nut with screw lock on the back. The screw lock only works if the screw protrudes at least 1-2mm from the nut. The screws on the Weedo X40V1 were too short and the screw loosened over time, leading to the adjustment of the belt tension. Longer screws for the pulley solved the problem for me.

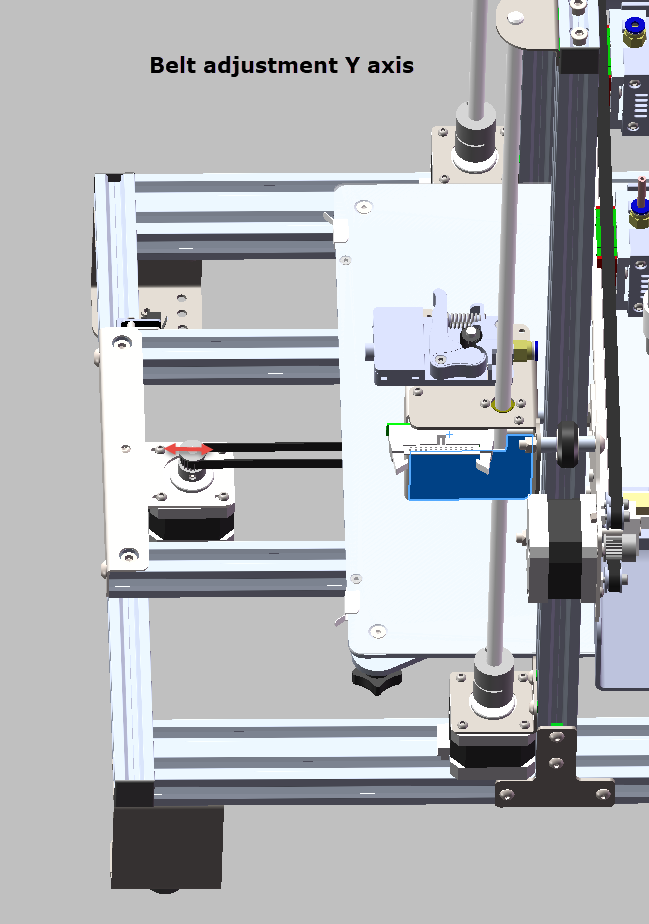

Belt adjustment Y-axis

The belt tension for the Y-axis is easily adjusted using the slotted holes in the stepper motor mounting braket.

To adjust, loosen all four screws. In doing so, loosen the two front screws significantly more than the rear ones so that the motor hangs tilted forward. Pull the motor backwards while tightening the rear screws. Then tighten the two front screws to create a slight belt tension.

- Youtube Video fom Weedo: X & Y Belt adjusting For WEEDO X40,X40V2