Materialflow test

The material flow is a very important parameter in an FDM printer in order to achieve a good print result.

The right material flow mainly depends on:

- FDM printer / Extruder calibration

- Nozzle size

- Material diameter / tolerance / charge

- Material manufacturer

- Material type

- Material color

The following failure can occur if the material flow is incorrect:

- Component not true to size

- Component detaches from the heating bed

- Warping

- Layer delamination

- Drops on the outer surface

- And much more...

It is therefore very important to determine the correct material flow for the printer and material used. To determine the material flow, we assume that the extruder is calibrated.

-> How to calibrate the Weedo X40 printer

Determination of the correct material flow

| The material flow is set correctly when the line width in the slicer matches the printed line width. |

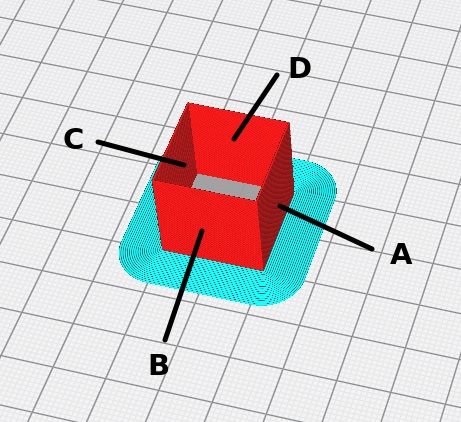

In order to determine the correct material flow, a rectangle made of just one line is printed. We use the 20mm cube (blank without letters) and set the following in Cura.

Download:

- 20mm x 20mm x 20mm Cube for flow adjust

- Material flow calculation tool (Open Office spreadsheet, can also be used with Excel)

Printing profile

| Default | normal |

Quality

| Layer height | 0.2 |

| Line width | 0.4 |

Walls

| Wall thickness | 0.4 |

| Wall line count | 1 |

Top/Bottom

| Top surface skin layers | 0 |

| Top/Bottom thickness | 0 |

Infill

| Infill density | 0 |

Material

| Flow | 100 |

Build plate adhesion

| Build plate adhesion type | Brim |

Special modes

| Spiralize outer contour | Yes |

Measure the walltickness with a digital caliper or even better with an micrometer. Measure each wall two times and average.

If the wall thickness does not correspond to the line width from the slicer, then you should correct the material foot.

Calculation the new material flow rate:

New flow rate = Nominal wallthickness / Measured wallthickness * Previous flow rate

Example:

Nominal wallthickness = 0,4mm

Average measured wallthickness = 0,455mm

Previous flow rate = 100%

=> 87,9% Flow rate

Deviations due to material tolerances

To be able to estimate how much the amount of material at the nozzle fluctuates, you only have to look at the tolerances of the filament. With a diameter of 1.75mm, the usual diameter tolerance is +/- 0.05mm. If the extruder pinion is now heavily worn and the diameter is smaller, then you quickly deviate significantly from the ideal. In addition, each material has a different shrinkage. If you do not pay attention to something like this, you can quickly print two lines that are right next to each other and have no or only a bad connection.

Let's take a closer look at the situation with the diameter tolerance:

| Diameter | Deviation | Cross sectional area | Theoretical flow | Difference |

| 1,70mm | 0,05mm | 2,270mm² | 94,38% | 5,62% |

| 1,71mm | 0,04mm | 2,297mm² | 95,50% | 4,50% |

| 1,72mm | 0,03mm | 2,324mm² | 96,63% | 3,37% |

| 1,73mm | 0,02mm | 2,351mm² | 97,75% | 2,25% |

| 1,74mm | 0,01mm | 2,378mm² | 98,87% | 1,13% |

| 1,75mm | - | 2,405mm² | 100% | 0,00% |

| 1,76mm | 0,01mm | 2,433mm² | 101,16% | 1,16% |

| 1,77mm | 0,02mm | 2,461mm² | 102,32% | 2,32% |

| 1,78mm | 0,03mm | 2,488mm² | 103,45% | 3,45% |

| 1,79mm | 0,04mm | 2,516mm² | 104,61% | 4,61% |

| 1,80mm | 0,05mm | 2,545mm² | 105,82% | 5,82% |

With a filament tolerance of +/- 0.05mm, the flow can change by approx. +/- 5.5%. There are also deviations due to shrinkage and wear. You can imagine that this large deviation has an influence on the print quality. In expensive printers, the filament diameter is therefore constantly measured by a sensor and the flow corrected. Other manufacturers save the sensor and offer filament with a tolerance of +/- 0.02mm (Prusament). Fortunately, the tolerance does not fluctuate constantly between the maximum back and forth, otherwise we would have big problems with over and under extrusion.

For printers without a filament diameter sensor, filaments with a maximum diameter tolerance of +/-0.03mm are recommended. If there are larger deviations, you may have to determine and set the correct material flow for a perfect print.

The following manufacturers offer filaments with small diameter tolerances:

| Manufacturer | Diameter tolerance |

| AddNorth | +/-0.025mm |

| Fiberlogy | +/-0.020mm |

| Material4Print | +/-0.020mm |

| Prusament | +/-0.020mm |

| Verbatim | +/-0.030mm |