Retraction test

On many FDM homepages, stringing problems usually suggest changing the retraction, which is only correct if the parameters are completely wrong or the retraction was deactivated. The main cause of stringing is usually a material that is too wet. So before you carry out retraction tests you should dry the material. Most of the time that solved the problem.

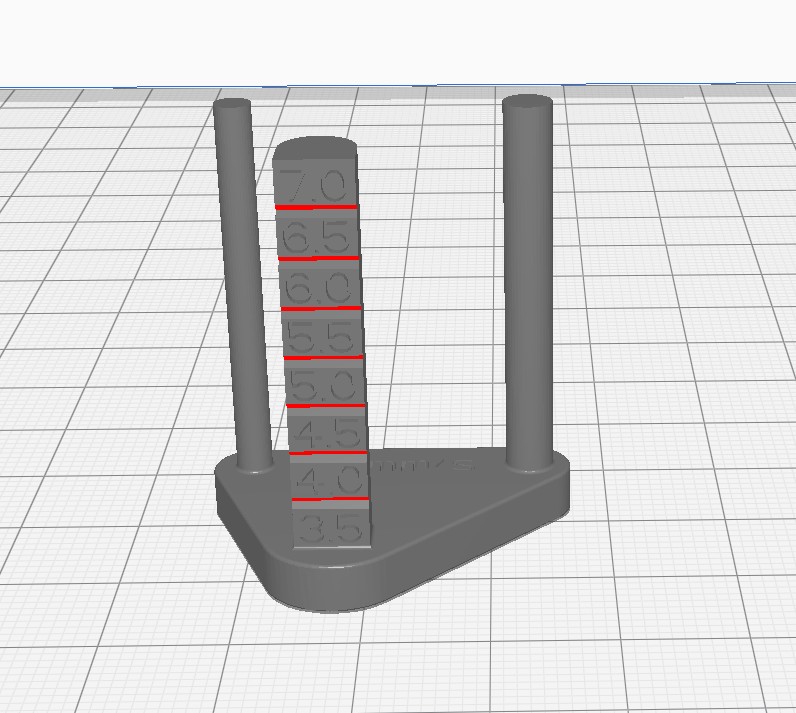

With the heat and speed test, we have determined the optimal printing temperature. The retraction test is about analyzing the string behavior of the material at the determined printing temperature. There are two parameters that are checked: Retraction Distance and Retraction Speed.

With a Bowden cable system like the one used by the X40, the usual values are:

- Retraction distance: 3-6mm

- Retraction speed: 20-50mm / s

Stringing occurs when the nozzle moves from one elevation to the next, pulling the material out of the nozzle. It is therefore important to activate the Enable Retraction in the Travel section if it has been deactivated. The cooling also has an influence on the strining. In addition, the moisture content in the material also has an influence on the stringing behavior.

Therefore, please only carry out the Retraction Test with material that has been freshly removed from the vacuum packaging!

Test parts with conical domes can often be found for analyzing string behavior. There will always be stringing with very splashy domes, as the material cannot be cooled quickly enough, so I do not find such tests useful. In our test part there are three domes with different distances. For a precise analysis, only one value may be changed for the pressure, so there is a new model for each retraction speed. The thread accuracy is also printed on the model. As the height increases, the retraction increases.

We start with a retraction of 3.5mm and end at 7mm.

A typical beginner's mistake is to set the retraction too high because you think a lot helps a lot. If the withdrawal is too high, the temperature can shift in the direction of the Bowden cable with many withdrawals. In extreme cases, the material can become soft in the Bowden cable and lead to a blockage.