Weedo X40 Community buildplate

Perhaps you have already noticed or found it in forums, the original Weedo buildplate is not exactly the flatest buildplate. This is particularly noticeable when you want to print large parts or distribute several on the platform. Anyone who is familiar with the manufacturing process knows that such a platform can never be completely flat. In particular for the Weedo Buildplate, various manufacturing processes were used (rolling, hardening, galvanizing) that do not exactly benefit the evenness.

In this article I want to introduce an alternative that I use and get good results with it. A glass plate is a very good solution but will not work with the Weedo X40 sensor as the sensor needs a magnetic counterpart. I have therefore chosen a mirror-smooth rolled, magnetic stainless steel plate. The steel is cold rolled and there is no further thermal treatment that warps the sheet. I also increased the sheet thickness of X6Cr17 (1.4016) to 3mm.

Material: 1.4016

| Country | Standadard | Description |

| Germany | DIN | X6Cr17 |

| USA | ANSI | 430 |

| Japan | JIS | SUS 430 |

| Unified Numbering System | UNS | S 43000 |

I ordered the sheet metal on ebay. You have to make sure that the material has the number 1.4016. The other stainless steels are only weakly or almost completely non-magnetic and the sensor does not work! There are also various dealers on the Internet where you can order the steel plate. If possible, you should have the corners provided with a 5mm radius.

Magnetic stainless steel buildplate 310mm x 310mm x 3mm with R5 corners.

Buildplate surface

Since you can't print on the steel surface (I tested it with spray adhesive), I need a build surface. There are various solutions to detach the component from the build surface:

- Magnetic build plate e.g. from Creality

- Build surface like Lokbuild and, for large components, the use of spray adhesiv

The magnetic building plate can be used excellently for PLA. However, the Creality product has problems with high temperatures around 250-260 ° C. If, like me, you use a lot of different materials, then a building board firmly glued to the sheet metal plate is better. To be able to remove large objects from the plate or to improve the adhesion, you should use an adhesion improver such as Dimafix.

- Creality Magnetic Build Surface

- LokBuild Permanent Build Surface

- LokBuild PEI Film (=> best solution)

- OSEQ Safe sheet 310x310mm

My clear recommendation is LokBuild PEI Film. This bed topper works very well with many common filaments. However, it must be ensured that the construction platform has cooled down before the printed object is removed, otherwise the surface can be damaged!

Why should I use Dimafix?

Dimafix is a water-soluble adhesion improver. The adhesive force is controlled via the bed temperature and is therefore significantly more independent of the material and the surface. With Dimafix you can not only increase the adhesive force of a material on the heating bed, but also reduce it.

You can find more information on the Dimafix homepage.

Cura plugin for different build platforms

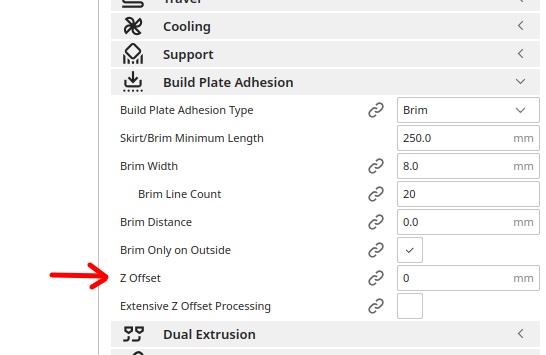

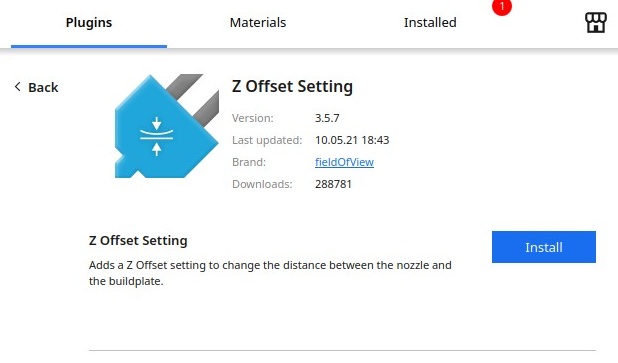

If you have build platforms with different thicknesses, then you should install the Z Offset Setting plugin from the Ultimaker Cura Marketplace.

After the installation you will find the new menu item Z-Offset under the Bulid Plate Adhesion menu. If the menu item is not displayed, activate the Check all item in the settings. All you have to do now is calibrate the printer to the thinnest build platform. In the case of thicker building plate forums, simply enter the difference to the thin building plate in the Z offset.