Material

Weight and dimensions of filament spools

In order to be able to determine whether there is still enough filament on the roll for printing, you need the roll weight for the calculation. Here is an overview of the common filament rolls from different manufacturers:

| Filament manufacturer | Filament | Spool size | Weight empty spool |

| 3DJake | All | ||

| AddNorth | All | 140 x 54 mm (100 - 250 g) 200 x 52 mm (500 - 1000 g) 200 x 52 mm (1000 g Economy lines) 300 x 52 mm (1500 - 2300 g) |

110 g (100 - 250 g) 215 g (500 - 1000 g) 235 g (1000 g Economy lines) 545 g (1500 - 2300 g) |

| colorFabb |

|

||

| Extrudr | All | 200 x 55 mm (750 - 800 g) 200 x 68 mm (1000 - 1100 g) |

230 g (750 - 800 g) 260 g (1000 -1100 g) |

| Fiberlogy | All |

|

324g (Completely) 258g (with one cheek) 192g (without cheeks)

|

| Fillamentum | NonOilen |

|

210g |

| Fillamentum | CPE HG 100 |

|

250g |

| Fillamentum |

|

||

| FormFutura | |||

| Igus | |||

| Material4Print | all 0,75kg |

|

215g |

| Polymaker | |||

| Prusament | |||

| Verbatim | PLA |

|

|

| Janbex | PLA |

|

270g |

- Details

- Hits: 6307

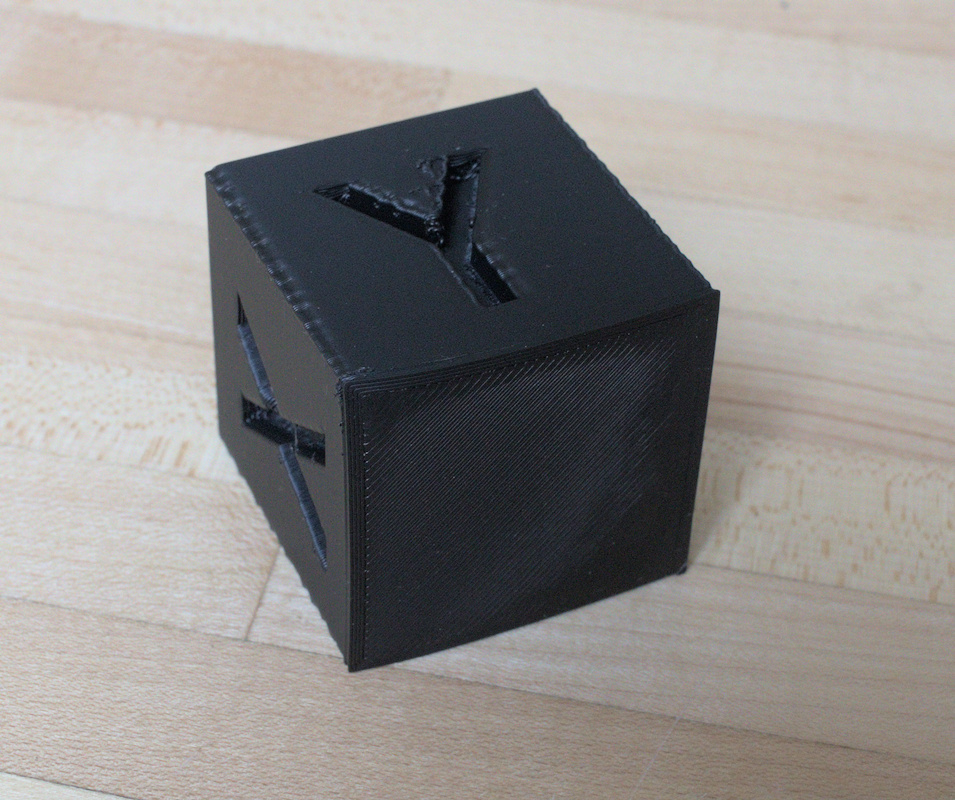

ColorFabb ALLPHA Filament

Several months ago, Fillamentum launched NonOilen, a filament that is produced entirely without petroleum and can be used in the garden without leaving microplastics. In June 2022, ColorFabb launched a similar product that is Polymer based completely different. We would like to introduce you to the brand new ALLPLA from ColorFabb and compare it with NonOlien.

What is PHA?

Some already know ColorFabb's PLA/PHA blend, which has better properties than standard PLA, but what exactly is PHA and what makes it so special?

It is produced by bacterial fermentation. Polyhydroxyalkanoate polymers (PHA) are produced by microorganisms (bacteria) and can also be completely eaten (decomposed) by microorganisms. Overfeeding the bacteria creates “fat cells”. PHA is a natural polymer that has not been chemically modified. PHA is fully biodegradable in your garden and therefore minimizes environmental pollution. The well-known PLA, on the other hand, can only be decomposed in an industrial plant at higher heat. PHA materials do not release toxic microplastics into the environment. PHA is not the same as PHA, as different types of bacteria also produce different types of PHA. It is difficult to use a PHA alone to make a filament. ColorFabb has therefore combined different types of PHA to produce the filament. ColorFabb only adds bio-friendly additives to improve material properties, effects and colors.

Even if all cost reduction potentials are exhausted, conventional PHA from microbial fermentation will be three times more expensive than bulk petrochemical polymers.

More information can be found here.

Filament properties:

- Is made from various bacteria without petroleum

- Is decomposed on the home compost by bacteria without microplastics

- PHA is biodegradable in salt and fresh water

- PHA is nontoxic and foodsafe

- PHA shows exceptional layer to layer adhesion in most printing conditions

- The material feels tough and capable and is stable to very high temperatures (>120C)

- Unlike other filaments, PHA needs to be printed on a cold bed!

- PHA have a low permeation of water. Drying is not required before printing

- PHA is completely jerk-free when printing

- PHA is not suitable for outdoor use, because it is not UV stable

- PHAs are soluble in halogenated solvents such chloroform, dichloromethane or dichloroethane

- Density: 1,24g/cm3

- Diameter Tolerance: ± 0.1 mm, available in 1.75mm and 2.85mm diameter

Download PDF: ColorFabb ALLPHA Technical Datasheet

Colors:

ColorFabb Allpha is currently only available in three colors and these are:

- Black

- Natural

- White

According to ColorFabb, the color palette is to be further expanded.

Printing guid:

The parameters depend on the nozzle diameter and the layer height. Here are the parameters for our Ultimaker Cura Visual Normal printing profile with a layer height of 0.2mm:

My Test environment:

- Printer: Weedo X40 PRO (with X40-Community Coolingsystem and Firmware X40 PRO)

- Nozzle: 0,4mm, Zodiac MK8 PRO

- Build platform: BuildTak PEI Film

- Slicer: Ultimaker Cura 5.0.0 with Weedo X40 PRO Configuration and Weedo X40 Thumbnail plugin

Weedo X40 Visual Normal printing profile for Cura 5.X

Quality

|

Layer height |

0.2 |

|

Initial layer height |

0.3 |

|

Line width |

0.4 |

|

Initial layer line width |

100% |

Walls

|

Wall Thickness |

1.2 |

|

Optimize Wall Printing Order |

True |

|

Wall Ordering |

Outside |

Top/Bottom

|

Top/Bootom Thickness |

1.2 |

|

Monotonic Top/Bottom Order |

True |

Infill

|

Infill Density |

20% |

|

Infill Line Distance |

7.2 |

|

Infill Pattern |

Cubic |

Material

|

Printing Temperature |

195°C |

|

Build Plate Temperature |

0°C |

|

Flow |

100% |

|

Horizontal Scaling Factor Shrinkage Compensation |

100% |

|

Vertical Scaling Factor Shringage Compensation |

100% |

|

Enable Linear Advance |

True |

| Linear Advance Factor (Needs Linear Advance Settings Plugin) |

0.25 |

Speed

|

Print Speed |

40mm/s |

|

Wall Speed |

20mm/s |

|

Top/Bottom Speed |

20mm/s |

|

Skirt/Brim Speed |

16mm/s |

|

Enable Acceleration Control |

False |

|

Enable Jerk Control |

False |

Travel

|

Retraction Distance |

5,5mm |

|

Retraction Speed |

30mm/s |

|

Combing Mode |

Not in Skin |

|

Retract Before Outer Wall |

True |

|

Z Hop When Retracted |

False |

Cooling

|

Enable Print Cooling |

True |

|

Initial Fan Spped |

0% |

|

Regular Fan Speed at Layer |

3 |

Support (If needed)

|

Support Z Distance |

0,2mm |

|

Support X/Y Distance |

0,8mm |

Build Plate Adhesion

|

Build Plate Adhesion Type |

None |

|

Brim Width |

8mm |

Experimental

|

Enable Bridge Settings |

True |

|

Bridge Has Multiple Layers |

True |

Tip for removing the print objects:

With larger parts, the adhesion to the print bed can become extreme and damage the component or print bed. For large parts, ColorFabb recommends heating the print bed to 90°C and holding it for about 15 minutes. The heat induces crystallization, which makes it easier to detach the printed part from the plate. Brim should not be used on small parts.

No stringing

Warping and unsightly edges

Test print for Linear advance k-factor

Maybe I haven't set the right bridge parameters in Cura yet, I can only print bridges up to 20mm in length. Other filaments can do this much better.

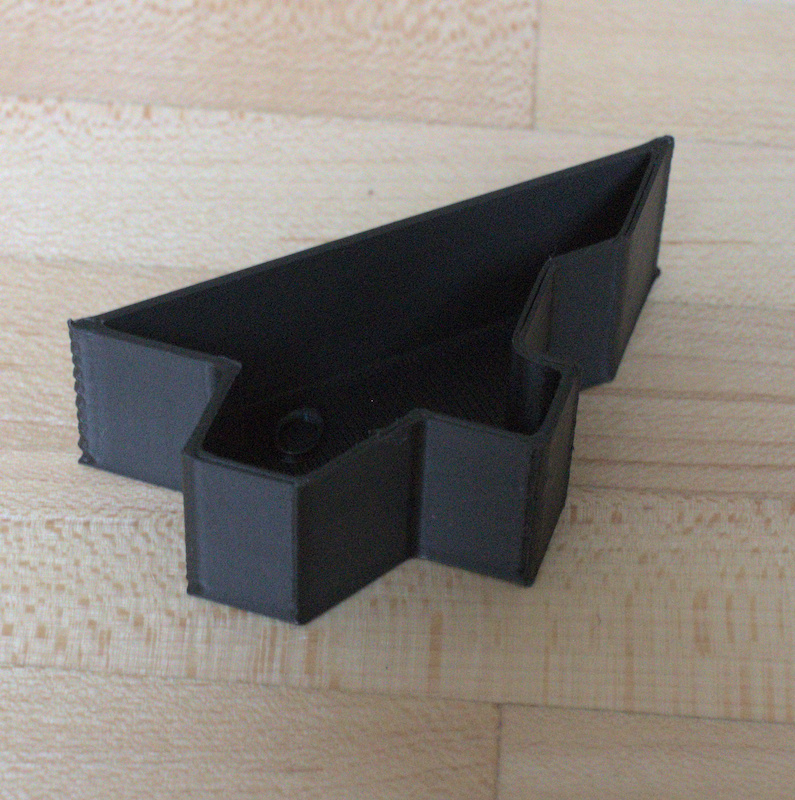

Material for support structures

The Beakeaway support structure works. The values for 0.2mm layer height can be found in the guide. Dissolvable support compatibility has yet to be tested.

Multi-material compatibility

The compatibility test with different filaments has not yet been carried out.

ColorFabb ALLPHA vs. Fillamentum NonOilen

ALPHA and NonOlien are both filaments that leave no microplastic behind. NonOlien offers print quality that does not differ from other filaments and can also be recycled very well. AllPHA has extremely strong lay adhesion and can withstand high temperatures.

You have to decide for yourself what is better for you.

Specification:

Source: Manufacturer's website, no guarantee of completeness and correctness

According to the data, ALLPHA is stiffer and more heat-resistant, but not quite as strong as NonOilen.

As usual, you can find my reviews below Tested Filament

- Details

- Hits: 19128

Material for support structures

With an FDM print, the print object is built up from the build platform. Depending on the material, slight overhangs and small bridges can be printed without material between the construction platform and the print object. However, a support structure is required for steep overhangs and large bridges. The support structure can be made of the same material as the print object or a soluble material. In the case of a support structure made of the same material as the print object, the corresponding parameters in the slicer / print profile must be set in such a way that the material can be easily cut out, but still creates a clean break surface. I recommend you to use the X40 Community print profiles and corresponding filaments, as the parameters there have been adjusted using appropriate tests.

However, there are materials in which the material properties are such that a support structure made of the same material cannot break out. These are e.g. the materials PP, OBC Polyethylene, TPU, PCTG but also some PET-G materials. This also often affects removal from the raft.

Supported breakaway materials

In order to make it possible to breakaway the support structure, the corresponding Cura parameters were optimized for all supported filaments (From Cura 4.11). Please note that temperature settings and removal of the support structure are related. Changing the print profile can therefore have negative consequences!

| Material | Designation | Breakaway | Remark |

| Standard PLA | PLA EASY PLA E-PLA Eco PLA |

Yes | |

| Tough PLA | Impact PLA X-PLA |

Yes | |

| Special PLA | PLA Mineral PLA Wood |

Yes | |

| PET-G | Yes/No | Some PET-G filaments have very good layer adhesion. Problems can arise with them. | |

| PCTG | No | The layer adhesion is so great that it usually doesn't work | |

| FiberSilk | Yes | ||

| FiberSatin | Yes | ||

| ASA | Yes | ||

| GreenTEC Pro | Yes | ||

| NonOilen | Yes | ||

| Nylon | ? | ||

| DuraBio | ? | ||

| PVB | ? | ||

| HIPS | ? | ||

| TPU | No | Material is flexible and has a very high layer adhesion | |

| PP | No | Material is flexible and has a very high layer adhesion | |

| OBC Polyethylene | No | Material is flexible and has a very high layer adhesion | |

| PMMA | Yes/No | PMMA has a high layer adhesion. If there is a large gap between the print object and the support structure, the support structure can be removed, but warping also occurs on the print object. | |

| PHA | ALLPHA | Yes |

In order to get clean surfaces on steep overhangs and large bridges or to be able to remove the necessary support structure, there is support material. The support material can be dissolved in a liquid without damaging the print object or the print object must then be heated so that the support material can be removed. Not every support material is suitable for every print object material. One of the reasons for this is the different temperatures, but also the adhesion.

Compatibility list for dissolvable or detachable support structures

Compilation by sources in the internet (no guarantee)

| Print-Objekt material | Support material | |||||||||

| BVOH | PVA | HIPS | P-support 279 | PolyDissolve S1 | PolyDissolve S2 | DPA-100 | VXL 70 | VXL 90 | VXL 111 | |

| PLA | X | X | X | |||||||

| PET-G | X | X | X | X | X | X | ||||

| PCTG | ? | ? | ? | X | ||||||

| ABS | X | X | X | X | X | X | X | X | ||

| ASA | X | X | X | X | X | X | X | |||

| TPU | X | X | X | X | X | |||||

| PP | X | |||||||||

| OBC Polyethylene | ? | ? | ? | ? | ||||||

| PVB | X | X | X | |||||||

| Nylon (PA) | X | X | X | X | X | X | ||||

| PC | X | X | X | |||||||

| HIPS | X | X | X | X | ||||||

| PHA | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? |

BVOH

BVOH is a water soluble support material that can be used with many plastic materials. BVOH dissolves significantly faster and more easily than PVA and, in normal quantities, can be disposed of via the sewer system without any problems. BVOH is inexpensive and absorbs moisture very quickly. Correct storage is therefore very important. It is best to print the filament straight from a dry box.

In the Weedo X40 Community Cura configuration there are print profiles for Fiberlogy BVOH and Verbatim BVOH.

PVA

Like BVOH, PVA can also be dissolved in water. The process just takes a little longer. The water can also be disposed of via the sewer system. For 3DJAKE nicePVA there are print profiles in the Weedo X40 Community Cura configuration.

HIPS

HIPS is actually a completely normal plastic for printing. HIPS can also be used as a support material, as it can be dissolved with a D-limonene solution. D-limonene, however, is not environmentally friendly and must not be disposed of via the sewer system. For environmental and health reasons, it is better to use the alternatives PVA or BVOH.

P-support 279

PP is a flexible and difficult to print material. It becomes even more difficult when you need a support structure for complex printing objects. P-support 279 is the only support material that adheres to PP, but can also be removed again. To remove the print must be heated to 100 ° C.

PolyDissolve

PolyDissolve are support materials from Polymaker. The support materials are optimized for Polymaker products, but can also be used with filaments from other manufacturers.

DPA-100

DPA-100 is support materials from colorFabb.

Unlike PVA our DPA-100 is less sensitive to moisture uptake and offers better shelf-life and print performance over time. DPA-100 support material is engineered to match with a variety of materials which can’t be supported by PVA due to bad adhesion to the build material. DPA-100 shows strong adhesion to PETG, ABS, ASA, PC and PA materials.

VXL

The Xioneer VXL support materials VXL 70, VXL 90, VXL 111, and VXL 130 print effortlessly, adhere to most model materials, and dissolve quickly. VXL support material has excellent adhesion to most thermoplastic materials. It bonds to PETG, ABS, TPU, PC, PA, and many other 3D printing materials like a strong glue. Unlike PVA or BVOH, our support material does not degrade in your nozzle even after prolonged exposure to heat. It is also less sensitive to air moisture, making VXL probably the most reliable support material you can find.

- Details

- Hits: 19511

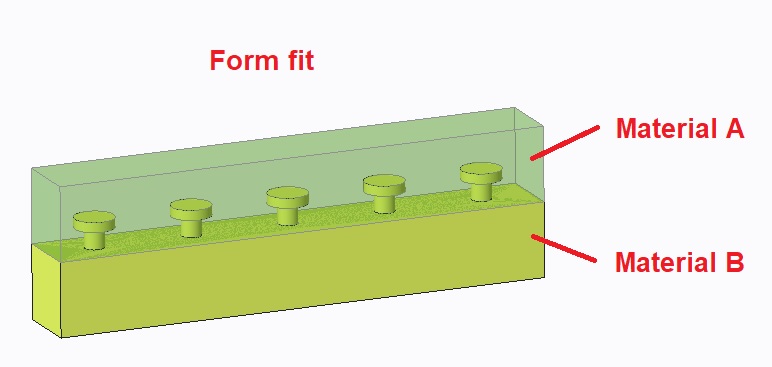

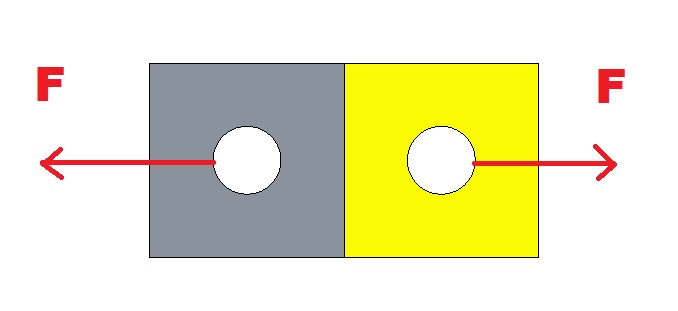

Multi-material 3D printing

Multi-material 3D printing is a 3D printing that consists of two or more components that are connected permanently or movably during printing. The best known is the two color printing with an FDM Idex printer. However, it is not only possible to combine two different colors from the same material. In this article I want to show the possibilities and problems.

Please also note the shrinkage issue.

Environmental Protection

Material combinations

Suitable material combinations enable interesting technical solutions. Typical examples for the combination of two plastics A and B are:

| Material A | Material B |

| Base color | Contrast color |

| Opark | Transparent |

| Hard / Stiff | Soft / Elastic |

| Standard material | ESD material |

| Standard material | Wear-resistant material |

Combinations with each other are also possible.

Requirements for combining different materials

Two different materials can be combined into one component in different ways. Two types of plastic can be fused together on the surface if they are compatible with each other. The compatibility is the better the more similar the materials are in the polymer composition. Materials that have a very different melting point can therefore not be connected to each other. However, two materials can also be connected to one another via a form fit. In the case of incompatible materials that do not enter into a material connection, you can also create flexible connections in this way.

Material / Filament compatibility

- Standard PLA = Material4Print PLA

- Tough PLA = Fiberlogy Impact PLA

- PETG = 3DJAKE PETG

- PCTG = Fiberlogy PCTG

- FiberSilk = Fiberlogy FiberSilk

- ASA = Fiberlogy ASA

- GreenTec Pro = Extrudr GreenTec Pro

- NonOilen = Fillamentum NonOilen

- DuraBio = Verbatim DuraBio

- PVB = Prusament PVB

- HIPS = Fiberlogy HIPS

- TPU = Polymaker PolyFlex TPU95A

- PP = Fiberlogy PP

- OBC Polyethylene = Addnorth OBC Polyethylene

- I150-PF = Igus I150-PF

- PMMA = Material4Print PMMA

- PHA = ColorFabb ALLPHA

| Material A / Material B |

Standard PLA | Tough PLA | PETG | PCTG | FiberSilk | FiberSatin | ASA | GreenTEC Pro | NonOilen | DuraBio | PVB | HIPS | TPU | PP | OBC Polyethylene | PMMA | I150-PF | PHA |

| Standard PLA | 3 | X | 1 | 1 | 2 | X | 1 | X | 3 | 1 | ? | 0 | 2 | X | 0 | 1 | 1 | ? |

| Tough PLA | 3 | 3 | 1 | X | X | 2 | X | 3 | 3 | 1 | ? | X | 2 | 1 | 0 | 1 | 1 | ? |

| PETG | X | 1 | X | 1 | 2 | X | 3 | X | 0 | 3 | ? | X | X | 1 | 0 | 1 | X | ? |

| PCTG | 1 | 1 | 1 | 3 | 1 | 1 | 1 | 1 | 0 | 1 | ? | 1 | 2 | X | X | 0 | 3 | ? |

| FiberSilk | 2 | X | 2 | 1 | X | 2 | 1 | X | X | 1 | ? | X | X | 0 | 0 | 0 | 1 | ? |

| FiberSatin | X | 2 | 1 | X | 2 | X | X | 3 | 3 | 3 | ? | 1 | X | 1 | X | X | 1 | ? |

| ASA | 1 | X | 3 | 1 | 1 | 3 | 3 | 3 | 1 | 2 | ? | 1 | 0 | 1 | 0 | 3 | 3 | ? |

| GreenTEC Pro | 3 | 3 | 2 | X | 3 | X | X | X | 3 | 3 | ? | 1 | 2 | X | 0 | 3 | X | ? |

| NonOilen | 3 | 3 | 0 | 0 | X | 3 | 1 | 3 | X | 0 | ? | 1 | X | 0 | 0 | 0 | 0 | ? |

| DuraBio | X | X | 3 | 1 | 1 | X | 2 | 3 | 0 | 3 | ? | 0 | 1 | X | 0 | 2 | 3 | ? |

| PVB | X | ? | ? | ? | ? | ? | ? | ? | ? | ? | 3 | ? | ? | ? | ? | ? | ? | ? |

| HIPS | 0 | 3 | 1 | 1 | 1 | 1 | X | 1 | 1 | 0 | ? | 3 | 0 | 1 | 0 | X | 0 | ? |

| TPU | 2 | 2 | X | 2 | 3 | 3 | 0 | X | 1 | 1 | ? | X | X | 1 | 0 | 2 | X | ? |

| PP | 3 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | X | 0 | ? | 1 | 1 | 3 | 3 | 0 | 0 | ? |

| OBC Polyethylene | 0 | X | 0 | X | 0 | 0 | 0 | 0 | 0 | 0 | ? | 0 | 0 | 3 | 3 | X | 1 | ? |

| PMMA | X | 1 | 1 | 0 | 0 | 3 | 3 | 3 | X | 2 | ? | 3 | 2 | 0 | 0 | X | X | ? |

| I150-PF | 1 | 1 | 3 | X | 1 | 1 | 3 | 0 | 0 | 3 | ? | 0 | 1 | 0 | 1 | 2 | 2 | ? |

| PHA | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | X |

- Details

- Hits: 17788

The correct storage of the filament is very important and is neglected by many. Many filaments are hygroscopic. That means they take in water. To protect against moisture, the filament is therefore vacuum-sealed together with a drying agent immediately after production.

The hygroscopic properties are different depending on the type of plastic. The properties change due to the moisture in the filament.

The following changes can occur:

- especially mechanical properties get worse, the material becomes more brittle, eventually more flexible

- stringing occurs a lot (fine hair when moving the nozzle)

- temperature and chemical resistance decrease

- layer adhesion gets worst, the entirety of the printed object is violated

- oozing occurs (accumulation of material on the side of the nozzle, which may lead to release and contamination of object), the nozzle can be clogged because of the accumulation of degraded material

With the Sovol Drybox, two narrow spools of filament or one width like Fiberlogy's can be dried. With narrow spools of filament, you can also print directly from the dry box.

Many misprints arise from incorrect storage or neglect of drying. Beginners who get a string usually try to eliminate the failer by changing parameters in the slicer, which is often the wrong way. Simply dry the filament or store it properly and the problems will not arise.

Overview hydroscop:

| Material | Properties | Dry time | Dry temperature |

| PVA | The water-soluble support material is extremely hygroscopic. The material can absorb water in just a few hours. Therefore only buy the amount you need or print out of a dry box. | 10-20h | 50°C |

| BVOH | The water-soluble support material is extremely hygroscopic. The material can absorb water in just a few hours. Therefore only buy the amount you need or print out of a dry box. | 4h | 50°C |

| Nylon / Polyamid | Polyamide can absorb water within a few times of wearing. | 3-8h | 60-90°C |

| PC | 4-8h | 70°C | |

| CPE | 5h | 75°C | |

| ABS | 2-4h | 80°C | |

| ABS/PC | 4h | 80°C | |

| ASA | 2-4h | 80°C | |

| PLA | PLA should also be stored in a dry place after printing, as it also absorbs moisture after several days. | 2-4h | 50°C |

| Impact PLA | 4h | 50°C | |

| PLA Mineral | 2-4h | 50°C | |

| PETG | PETG should also be stored in a dry place after printing, as it also absorbs moisture after several days. | 4h | 65°C |

| TPE | 2h | 80°C | |

| TPU | 3h | 80-100°C | |

| NonOilen | 2h | 70°C | |

| FiberSilk | 2-4h | 50°C | |

| Fiberwood | 2-4h | 50°C | |

| PP | No water absorption that affects print quality | - | - |

| HIPS | No water absorption that affects print quality | - | - |

Correct filament storage:

Store the filament in a very dry place, at room temperature and out of direct sunlight.

An airtight, lockable PP plastic box with desiccant is recommended for storage. The box should be made of PP, as the material allows very little moisture to pass through. A color indicator for the degree of moisture is helpful for the desiccant.

The following products are recommended for storage:

-

IRIS OHYAMA Water Proof Box + Silica Gel Orange Desiccant Indicator Green Regenerable Dehumidifier

- Vacuum set including pump

- Details

- Hits: 19279